La historia no contada de ETU-LINK: Los héroes anónimos que protegen la calidad de los módulos ópticos

En el taller de producción de módulos ópticos de

ETU-LINK

Comunicación Óptica: no hay focos, solo un grupo de empleados comunes trabajando en silencio. Día tras día, se mantienen fieles a sus puestos, empleando sus técnicas expertas y un gran sentido de la responsabilidad para garantizar la calidad de cada módulo óptico. Estos productos llevan la etiqueta "Hecho por..."

ETU-LINK

" se envían a diversos lugares con esta dedicación, convirtiéndose en componentes centrales para el funcionamiento confiable de las redes de comunicación.

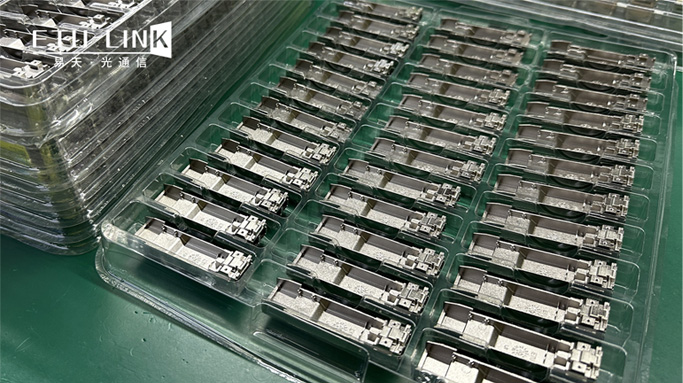

En el taller, el

Los puestos de inspección de calidad, montaje y pruebas son los más representativos

Cada empleado en estos puestos desempeña sus funciones, utilizando su experiencia para construir una sólida defensa de la calidad. El equipo de inspección de calidad actúa como el "centinela de la calidad" durante todo el proceso de producción. No solo verifican las especificaciones, el rendimiento y la apariencia de los componentes entrantes, sino que también inspeccionan aleatoriamente los productos semiacabados durante el ensamblaje, identificando rápidamente cualquier problema que pueda surgir. Identifican posibles problemas y evitan que los productos defectuosos pasen al siguiente proceso.

La línea de montaje es crucial para la "formación" del módulo óptico.

Siguiendo procedimientos estandarizados, los empleados ensamblan las piezas dispersas una a una para formar un producto completo. Con destreza, son meticulosos con cada detalle del ensamblaje: que las piezas encajen perfectamente, que las interfaces estén alineadas con precisión y que la estructura esté firmemente fijada. Cada acción refleja su dedicación a la calidad, transformando las piezas frías en módulos ópticos completamente funcionales.

El equipo de pruebas se considera la "prueba definitiva" para el control de calidad.

Los empleados operan instrumentos de precisión para realizar pruebas exhaustivas de indicadores clave como el rendimiento de transmisión y la estabilidad de los módulos ópticos. No solo registran con precisión cada conjunto de datos para determinar si el producto cumple con los estándares, sino que también simulan diferentes escenarios de aplicación para las pruebas. Incluso la más mínima anomalía en los datos se verifica repetidamente y se rastrea hasta su origen para garantizar que cada módulo óptico que sale de la fábrica...

poder

resistir el escrutinio del mercado.

Estos empleados en estos tres puestos clave pueden tener roles diferentes, pero su sentido de la responsabilidad es el mismo. Durante un descanso, charlé con el personal de inspección de calidad, quien comentó que, además de revisar los materiales, también patrullan con frecuencia la línea de montaje. "A veces, las piezas no se ensamblan correctamente y es fácil pasarlas por alto si no se tiene cuidado. La detección temprana significa una reelaboración temprana". No realizan hazañas trascendentales; simplemente cumplen discretamente con sus responsabilidades en sus puestos habituales con técnicas hábiles y una actitud meticulosa. Desde la llegada del material hasta la entrega del producto, el control de calidad en cada etapa del proceso refleja su arduo trabajo y dedicación.

defendiendo colectivamente la reputación de calidad de "

ETU-LINK

Fabricación"

.

Estos dedicados empleados de primera línea, que trabajan incansablemente día tras día, son como los componentes discretos pero cruciales de un módulo óptico. Aparentemente comunes, respaldan el funcionamiento estable del producto. Su compromiso inquebrantable permite que "E"

TU

-Sky Light" para cruzar montañas y mares, entregando confiablemente su energía a cada rincón del mercado en todo el país.

Son la base sólida de

ETU-LINK

Garantía de calidad y un microcosmos vívido de trabajadores de primera línea en la industria manufacturera de China. Es esta dedicación y responsabilidad arraigadas en sus puestos lo que ha permitido

"

ETU-LINK

Calidad" para afianzarse en el mercado y también ha permitido que el mundo vea la sólida fuerza y la artesanía transmitidas desde la primera línea de la industria manufacturera de China.

.

Categorías

nuevo blog

Etiquetas

© Derechos de autor: 2026 ETU-Link Technology CO ., LTD Reservados todos los derechos.

Soporta red IPv6